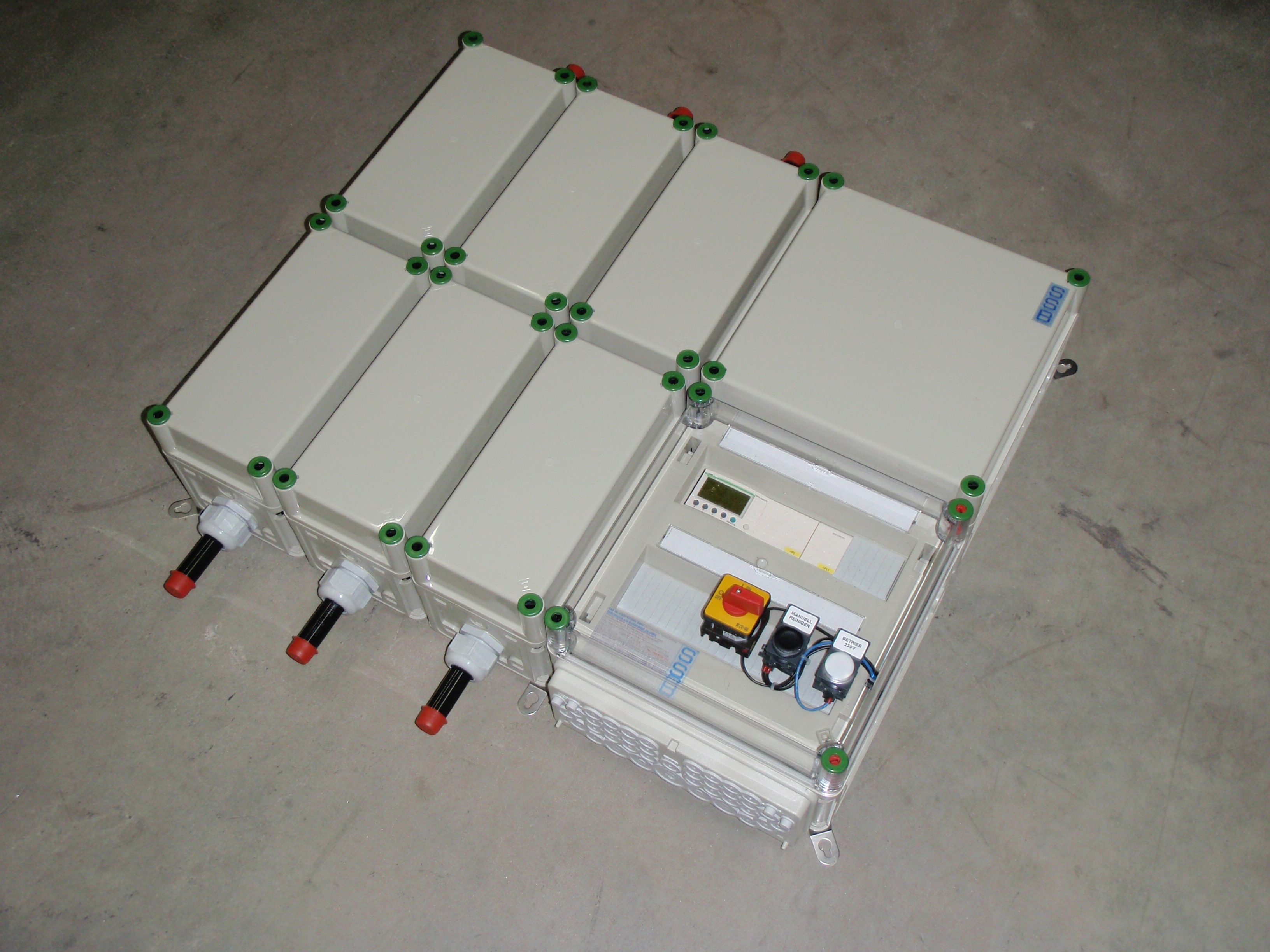

Techconnet offers automatic

Air-Blast Systems for all professional

Smoke Aspiration Detectors with 1 to 4 sensor pipes.

The operational safety of

aspirating smoke detectors can be significantly increased. Customers benefit

this way permanently and sustainably. The Techconnet "BlowOff" Air-Blast Units,

tested in accordance with EN 54-20 standard, enable trouble-free maintenance of

the air-flow-monitoring of the ASD through permanent removal of dirt-and dust

in the sensor pipes. Therefore, sensor pipe related faults and failures of ASD can be prevented.

Product features:

durable, high performance industrial components

The control is carried out automatically by a PLC timer with a specially developed control program

Large-inch valves guarantee unimpeded suction pressure

Easy installation and quick coupling for compressed air supply

compact, powder-coated metal housing

Casing door can be folded down and locked twice.

Blow-out times pre-programmed four times daily (01:00, 07:00, 13:00, 19:00) or individually

programmable in freely selectable intervals

Each sensor pipe can be cleaned non-scheduled manually or optionally triggered by the

ASD

Input contact is available to deactivate the cleaning in process in case of pre-alarm or

alarm of the fire detection system

Output contact is available to prior notification of a cleaning interval to the smoke

aspiration detector and/or the fire alarm system in order to prevent fault messages of the

fire dtection system during the air-blast process

Free output contact via potential-free (normally open) contact for other signaling or switching

purposes

Optional: adjustable, integrated control cabinet block heating with thermostat for safety even at

lowest outside temperatures

Optional: compressed air monitoring

Existing ASD systems can be retrofitted / upgraded on site

Areas of application

Automatic maintenance of Smoke Aspiration Detector Systems is particularly useful

in harsh environments. If ASD are very often disabled due to dust, moisture, micro-conditions and aggressive air,

Aspiration Smoke Detectors should be retrofitted with Air-Blast Systems.

Waste management

Train / subway stations

Mining

Chemical industry

High-bay warehouse

Wood industry

Cathedrals

Food industry

Exhibition halls

Metalworking

Mills

Museums

Paper industry

Cement industry

Product versions:

BO 2.1 HD Automatic Air-Blast System with one pipe

Automatic Air-Blast device "BlowOff" for fully automated

cleaning of sensor pipes of Aspirating Smoke Detectors. Suitable for connection of a single-pipe

system up to max. 300 m pipe length.

The Air-Blast Device is installed directly between the aspirating

smoke detector and the pipe network. It cleans the sensor pipe by means of compressed air. By controlled

air-blast of the sensor pipes existing pollutions are removed, new deposits are prevented.

Technical specifications:

1-pipe system

Operating voltage 230 V AC or 24 V DC

Dimensions W x H x D (mm) 700 x 500 x 250

IP Rating IP 65

Protection class 1

Temperature

range from + 40 ° C to -5 ° C; (with heating - optional + 40 ° C to -20 ° C)

Tested by VdS according to EN 54-20 standard with aspiration smoke detectors

manufactured by Wagner and Honeywell/Xtralis (VESDA). Tetst with further brands are in progress.

BO 2.2 HD Automatic Air-Blast System with two pipes

Automatic Air-Blast device "BlowOff" for fully automated cleaning

of sensor pipes of Aspirating Smoke Detectors. Suitable for connection of a two-pipes system or two single-pipe

systems up to max. 300 m pipe length.

The Air-Blast Device is installed directly between the aspirating

smoke detector and the pipe network. It cleans the sensor pipe by means of compressed air. By controlled air-blast

of the sensor pipes existing pollutions are removed, new deposits are prevented.

Technical specifications:

2-pipes system

Operating voltage 230 V AC or 24 V DC

Dimensions W x H x D (mm) 700 x 500 x 250

IP Rating IP 65

Protection class 1

Temperature

range from + 40 ° C to -5 ° C; (with heating - optional + 40 ° C to -20 ° C)

Tested by VdS according to EN 54-20 standard with aspiration smoke detectors

manufactured by Wagner and Honeywell/Xtralis (VESDA). Tetst with further brands are in progress.

BO 2.3 HD Automatic Air-Blast System with two pipes

Automatic Air-Blast device "BlowOff" for fully automated cleaning of sensor pipes of Aspirating Smoke Detectors. Suitable for connection of a three-pipes system or three single-pipe systems or

a two-pipes and a single-pipe system up to max. 300 m pipe length.

The Air-Blast Device is installed directly between the aspirating smoke detector and the pipe network.

It cleans the sensor pipe by means of compressed air. By controlled air-blast of the sensor pipes existing pollutions are removed, new deposits

are prevented.

Technical specifications:

3-pipes system

Operating voltage 230 V AC or 24 V DC

Dimensions W x H x D (mm) 700 x 500 x 250

IP Rating IP 65

Protection class 1

Temperature range from + 40 ° C to -5 ° C; (with heating - optional + 40 ° C to -20 ° C)

Tested by VdS according to EN 54-20 standard with aspiration smoke detectors manufactured by Wagner and Honeywell/Xtralis (VESDA). Tetst with further brands are in progress.

BO 2.4 HD Automatic Air-Blast System with four pipes

Automatic Air-Blast device "BlowOff" for fully automated cleaning of sensor pipes of Aspirating Smoke Detectors. Suitable for connection of a four-pipes system or four single-pipe systems or

two two-pipes systems or a three-pipes and a single-pipe system up to max. 300 m pipe length.

The Air-Blast Device is installed directly between the aspirating smoke detector and the pipe network. It cleans the sensor pipe by means of compressed air. By controlled air-blast of the sensor pipes existing pollutions are removed, new deposits are prevented.

Technical specifications:

4-pipes system

Operating voltage 230 V AC or 24 V DC

Dimensions W x H x D (mm) 700 x 500 x 250

IP Rating IP 65

Protection class 1

Temperature range from + 40 ° C to -5 ° C; (with heating - optional + 40 ° C to -20 ° C)

Tested by VdS according to EN 54-20 standard with aspiration smoke detectors manufactured by Wagner and Honeywell/Xtralis (VESDA). Tetst with further brands are in progress.